MAKING SHOTSHELLS IN .357 MAGNUM CASES WITHOUT USING A CAPSULE.

By Kevin Newberry

I’ll start by saying we won’t be reinventing the wheel here, but we will eliminate the shot capsule. I’ve listened to good opinions and watched some videos where good tips were picked up.

Since I like to recommend Ramshot True Blue as THE ONE POWDER with its pressure stability and ballistic uniformity compared to the other powders it dethrones in the hypothetical question: if I could have only one handgun powder? There is no data available for this job using True Blue. My decision to use it along with the two characteristics just mentioned is because of the higher charge-weight vs the smaller space it occupies in the case.

I’ve really wanted to play around with such loads ever since I bought the SPEER #11 reloading manual back in the mid-1980s, but I’ve just bought the CCI product instead, due to convenience. Using the capsules is easy enough using their recommendation of #9 shot and following their instructions for seating the capsules, but the articles I read along the way when a capsule was not used were of particular interest to me. I used the SPEER #11 data to extrapolate the charge of True Blue I’ll start with. There are two powders in that data that have long been discontinued with W630 and HS5. They were phasing out at the time of that manual. I know from comparing a couple of powders to W630 that Accurate No 7 is similar in burn rate to W630 while True Blue is more similar to the old HS5. The other powders I used for the extrapolation are Unique and W231. Two other alternate powders I have are Accurate No 2 and W231 where data is available for the shot capsules. The 3rd and 4th possible choice I have would be Accurate No 7, or if you have No 5, why not? Patterns will let you know how effective the chosen powder is, while the effective velocity window appears to be 1000 – 1100 FPS. The SPEER #11 states that the .38/.357 loads were tested from a 6″ barrel, and velocity loss from a 4″ barrel could be as much as 150 FPS

I suppose that one reason I’m so late in doing this project is because I never really got excited about filling a shot capsule with #9 pellets. The .44 Special and Magnum loads, as well as the .45 Colt, allow for larger shot, but within the limits for the capsules, if they’re used. Pellets can be as large as 7 ½ shot, so why not .357 Magnum? Rather than use a capsule that’s largely meant for .38 Special, I wanted to make loads specifically for .357 Magnum revolvers where cartridge pressure won’t be much different than .38 Special anyway. It does, however, provide for more shot landing in a given practical diameter than the capsules allow using #9 shot. I am also aiming for the velocity that SPEER got from a 6” barrel since my loads will be used from a 4.2” GP100 and a 4” S&W 686+.

Most recently, a couple of developments occurred. The first came from reviewing the Hornady catalog and looking at the results by using their Star Crimp die made for loading blanks. I got very interested in seeing what I could do if I used a .357 Maximum case where after the crimp is applied, the OACL should be at or under the SAAMI Max Recommended OACL of 1.590” for the .357 Magnum. I won’t say at this point that I won’t try this later, due to the amount of shot that could be used, but the Hornady die comes in a 2-die set where cost is a bit prohibitive at over $100 retail on top of the cost of buying .357 Maximum cases. If True Blue works well in my .357 Magnum cases, I suspect there would be little difficulty in finding a good charge for loading .357 Maximum cases later, but most of us whom have an interest in this already have .357 Magnum cases. The other development came from a neighbors garage cleaning where about half a bag of old 7 ½ shot was discovered, and his wanting to dispose of it. If this works as planned, I’ll have plenty of shot for future loads.

Now, let’s look at the direct comparison. Obviously, there are more pellets of #9 shot that can be used in the capsules. One writer put that at 135 pellets. I haven’t counted pellets yet, but the weight of the 7 ½ shot I was able to get between the wads is around 98 grs; leaving space above the top wad and melted wax. On the evening of November 4th, I made the 1st test rounds, and I encountered a problem right off the bat. I made the first wads from plastic that came from disposable food containers. I always like to mention with my recommendations for True Blue that it is very dense (975 grams/liter), very fine-grained and meters like hourglass sand. The plastic wads would not prevent True Blue from leaking past them. I should also mention what Rob Behr and I discussed some time back, when we were discussing methods for loading handgun shotshell cartridges, and that was using a gas-check as the wad between powder and shot. One writer mentioned this as well for his method for loads he made for the intended purpose of shooting barn rats; but at 20′ the gas-checks can still penetrate 1/2” of plywood. Not an issue for loads only used outdoors, but could be hazardous for shooting inside a barn, or should an adventurous squirrel find his way into your house. Since gas checks are available in quantities of 1000, I even considered using 2 gas checks with second one atop the shot pellets where a substantial roll crimp could be applied. Not knowing how that might affect patterns, I elected to try cardboard wads, cut in cookie cutter fashion with the case-mouth of a cartridge reamed and chamferred to a sharp edge.

The load I’m looking for is primarily for snakes, and in hunting vernacular, if I have to use them, I want the snake DRT, Dead Right There. This is rattlesnake country of the diamondback variety. But in nearly 25 years of living in the same residence, I have yet to encounter a diamondback in my yard. For my shooting partner, Randall, he lives in a much smaller town about 35 miles NNW of here. Any outdoor project he’s involved in where debris has to be hauled away, their debris dump is outside of town in a remote location.

Now, as Paul Harvey used to say, “and now, the rest of the story.” Mowing my lawn in May of 2015 with a push mower set up for mulching, I was in the backyard about a dozen feet behind my house. I had to go to red-alert in a hurry. I saw a large snake I estimated to be at least 4′ long-headed right at me. First reaction? Look for the diamond patterns on its back: there were none. Instead, there was the unfamiliar pattern of some types of oak leaves instead, and the spade-shaped head of a viper. Second reaction? Pull the mower a little closer to my body and then give it a good push. At that point I figured any snake heading towards me like a heat-seeking missile and only about 6′ away was a snake in need of killing. My mulching mower was quite effective in turning the snake into bird food, but to my surprise, it was a copperhead. I didn’t know that they got this far West, and within a month, Randall had a similar occurrence 35 miles away. Being on the outskirts of a very small town, he used a 12-gauge to resolve the matter. Must have been one of those odd summers as was the case in the movie Predator.

Another point I should make is the estimate for patterns the capsules loaded with #9 shot will make at around 1” per foot of distance. With the maximum effective distance of say 20′, patterns should be around 20”. That’s more area than I’m concerned with. If I can get smaller patterns at the same distance by using the 7 ½ shot pellets, I’m hoping to see a good saturation of the pellets within the pattern. Each pellet of the shot having higher energy and momentum than that of #9 shot.

The leakage of True Blue was solved by cutting a wad of cardboard, like from say, a cereal box, or from the box containing your favorite beer. They were surprisingly firm in their fit and stopped any leakage. Now lets reconsider alternate powders. Accurate No 5 & No 7 have grain size and bulk density not much different from True Blue. In a past article here on the blog, Accurate No 2 was used to good effect in handgun shotshells with #12 shot and it’s a bit larger grained with lower bulk density than the other Western Powders mentioned. W231 is easily the largest suitable powder I have in grain size, and with maybe ½ pound of it remaining, it would be a good way to use it up if need be. Testing with a LEE .5cc dipper I got the same charge-weight of 4.8 grs. From both No 2 and W231. That’s a case of smaller granules of much lower bulk density vs higher bulk density with larger grain size with W231.

For other chores, I should have looked at No 2 more closely, much sooner than I did. How I first came into using it actually came from .45 ACP handloads. W231 has never been particularly impressive to me as some recommendations might lead you to believe, and then there are the velocity limitations in using it for defense loads with JHPs. Particularly at 230 grs. where I favor True Blue; Silhouette for speedier 200 and 185 gr. JHP defense loads. And for me, personally, W231 was even less impressive for light, target, or bunnyfart loads with 200 gr. SWCs. I took to using WST for that while W231 has actually worked better for target loads in 9mm and .38 Special. So, the question became what powder could I use to replace the 2 Winchester powders? Ramshot ZIP can be used for similar purposes and can be surprisingly accurate in 9mm target loads. But so far I’ve made some excellent RMR 124 gr. In-House 9mm JHP loads for gun games at near 130 Power Factor. 125 PF +5 for a safety cushion. I know that most of the gamers believe that 147 gr. JHPs will have lower recoil at the same power factor, but one has to wonder about how much of that comes from the tendency to follow the herd? After all, Power Factor is a good indicator for recoil. With No 2 at 4.2 grs. (properly worked up to) with the RMR 124 gr. In-House .355” JHPs at an OACL of 1.122”/28.5mm and a CCI500 primer, recoil is not what will prevent the best scores while standard deviation is typically at or below 5 FPS. Be sure to confirm the OACL that can be used for YOUR pistol when loading the RMR 124 gr. JHPs that are similar in shape and very competitive with the Nosler JHPs of the same weight.

Another issue I will mention is that until recently, a large number of gun gamers were using TiteGroup or Clays in their 147 gr. JHP loads. Unfortunately, Clays, as it came from ADI in Australia is no longer imported into the US and its Canadian replacement has not proven to be its equal. In high-pressure cartridges in particular, TiteGroup is one of the hottest burning handgun propellants you could use. Hot enough to cause some incidences of melting the fiber optic front sights, smoke with hard-cast bullets, while melting the polymer from the base of poly-coated bullets. Don’t take my word for that since I am writing this article for the Western Powders blog; check on competition-oriented gun forums like Brain Enos’ forum. And more recently, powders like W244 and Alliant Sport Pistol were designed with poly-coated bullets in mind. What I don’t understand is why more shooters haven’t tried Accurate No 2! Like TiteGroup, it is insensitive to powder positioning, and with either 124 or 147 gr. JHPs in 9mm loads, you’ll be in the powders upper-pressure range at or near 130 PF. That’s also quite a benefit for .45 ACP loads where most powders used will not take up a lot of the available powder space. With the 125 & 158 gr. .358” Plated Hollowpoints from RMR, No 2 is going to get a substantial test in our .38 Special and light .357 Magnum loads. It’s already showing promising results in .38 Special. To test its insensitivity to powder positioning I will load lower velocity start charges in .357 Magnum cases.

After the first handloading session there will be some changes. I used melted wax to seal above the top wad. Another tip came that advocated using hot glue. Rob and I kicked that around where a couple of points were discussed. Mine being concern about any residue from the glue remaining in the bore and Rob mentioning how well the glue might adhere to the case. One thing I did notice from the cookie-cutter approach is that it seems that the plastic discs are a bit easier to cut than those from cardboard. Future loads will have a plastic wad above the shot in hopes that the hot glue will fuse with the plastic, and a better seal for storage or foul weather concerns. For the wad between True Blue and the 7 ½ shot, if the patterns are not what they should be from the first loads, I may add a plastic wad over the cardboard wad sandwiched between powder and shot for more rigidity.

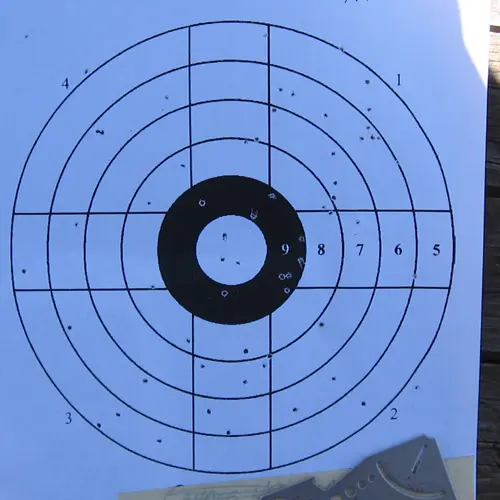

The first shooting trials using the wax over wad method was encouraging except that the wax proved messy in making a seal. There were other shooters at the range, so I wasn’t able to change targets for each of the 2 tests. The first round performed well and the second was a duplicate. The vast majority of the pellets stayed within the outer scoring ring that measure 7.5” in diameter while the distance to the target was 10′. The charge of True Blue I extrapolated from other powders from the SPEER #11 manual is 6.5 grs. And I used a CCI500 primer.

I can’t say that I had an epiphany before making the second group of loads, but I did make a couple of last-minute changes besides switching to hot glue as the sealer. I decided to skip the top wad altogether. Since I didn’t have another partial tray of CCI500s, I thought I’d like to test with CCI550s at some point, anyway, and I had a partial tray that helped in that decision. The powder charge of 6.5 grs. of True Blue remained the same. Chronographing was not easy in the first trial, but it appeared that velocity was just over 1000 FPS, so call me lucky! Not so lucky was not being able to find the glue gun and sticks I thought I had. That was promptly solved by my wife making a trip to Wally-World. It didn’t take but a few loads for me to decide I liked working with the hot glue much better. I made 24 rounds and nearing the end I found that I could shape the glue somewhat. I have a couple of .38/.357 die sets, so I used my older Lyman seat/crimp die. I didn’t give a lot of thought beforehand regarding the seating stem, so I used the flat-nose type. Near the end of the loading session, with the luck I was having sealing with hot glue, I wished I had used the round-nose seating stem. Because I had not achieved great enough consistency with shaping the glue, I went with the original gameplan to cut the glue back to the case-mouth, with all but one. I also found that I needed to remove a couple of pellets from some cases to get a similar space for adding the glue. Right around 1/8” thick after trimming.

At our next range session, late on a Wednesday afternoon 12/4/2019, there were no other shooters at the range. Setting up the portable target stand at 10′ with the chrono just a couple of feet ahead of it, velocity went up closer to 1100 FPS for the loads shown that had the magnum primers. Still having some of the original loads with the wax seal, they chrono’d close to 1050 FPS. There was not a great deal of difference in the size of the patterns however. Thankfully, I did not ruin a chronograph!

The first round tested was with the one round where I did not trim the seal/wad. I wondered beforehand what would happen to the glue “bullet.”

The trimmed glue seal/wad round performed a bit better throughout the pattern and in the center particularly. Counting pellets in the blackened 9-ring, and the 3 in the 10-ring, that’s a total of 12 pellets, or around 16% of the pellets. I would have no problem using this load on snakes. One aspect that I am very pleased with is the roughly 7.5” patterns at 10′. And since I’m fairly proficient in shooting the 4.2” GP100 double-action, I would likely fire more than a single round, anyway, which led to another test. I fired 6 consecutive rounds of the wax sealed load into a single target, and 6 consecutive rounds of the trimmed glue load into another. This to prove that the pattern size remains the same for either. There was a slight advantage for the wax-sealed over cardboard wad loads in terms of the number of pellets that landed in the 9 & 10-rings. This I attribute to the higher velocity of the trimmed glue load that had the magnum primers, but, the difference is slight. Overall, the pattern size does not change, not even with 6 rounds fired into each target. And this from a 4.2” barrel rather than the 6” barrel used in the SPEER #11. I mentioned before that pattern sizes might be half as large in diameter with the heavier shot, and if you use a 6” .357 Magnum for your tests, the patterns should be reduced to an even smaller diameter, but a slight reduction of the powder charge may be required, by say .2 grs. A 25% percent reduction in the pattern size ranks to me as a success because I’ve essentially matched the velocity of the loads fired from a 6” revolver. Compared to articles I’ve read, I’m actually getting more pellets into the pattern than you would by using a shot capsule filled with #9 pellets. A Security-Six is what they used for the .357 Magnum data, and I suspect for the shotshells as well. And SPEER states that if fired from a 4” revolver, you should expect to lose 150 FPS.

Along with smaller patterns as a goal, the larger 7 ½ pellets each have greater energy and momentum than 9-shot, and definitely a reason for using them; not just to eliminate the shot capsule. I will also say that if your field revolver has a 4” barrel, I can recommend the 6.5 gr. Charge of True Blue and a standard small pistol primer. And not just because it’s my favorite handgun powder. Weight of the charge while leaving adequate space for the hot glue seal/wad is 95.1 grains +/- while the pellet count is approximately 77. Since there are fixed target stands at 7, 15 and 25 yards at our range, I shot a target at 7 yards and the load still performed well; although that’s probably a little further away than a shot I’d likely take on a snake.

Now to continue on. What I expect will be the final loads will only get a change of primer. I busted a full tray of CCI500s this time. One of the reasons I wanted to try the CCI550s is because I use a magnum primer for .38 Special loads charged with True Blue. Usually with 158 gr. Poly-coated SWCs or JHPs.

Sunday, 12/8/19, I made what I expect will be the final round of test loads, particularly if the standard primer and slightly lower velocity put a good number of pellets into the center, or 9 & 10 rings.

Now would be a good time to give some tips I think will help. Once you insert the cardboard wad to cover the powder charge, I found that a 5/16” drill bit, chuck end down, makes a good ramrod. Once it contacts the powder, press firmly using something over the bit to protect your hand, and rotate the case to ensure a good seal. I used a funnel to pour the shot, and I recommend pouring the shot in slowly. It seems to settle better. I decided to stay with the method of cutting the glue back to the case-mouth. And while I didn’t like using the hot wax, I did find a good use for one of the lighted candles: heating the blade of my Exacto knife. I had some questions along the way about skipping the top wad over the shot. Pouring the hot glue into the case and over the shot will give you a thickness of around 1/8” after you cut the glue back to the case mouth.

I didn’t set out to make the shotshells with the intention of economizing. The cardboard you already have along with the cases, primers and maybe a suitable powder. That only leaves the shot to buy, and the mini glue gun and glue sticks if you don’t already have them. I did see one video method where the handloader used the larger, and maybe standard size glue sticks alone, and they seemed to fit closely to the inside diameter of the case. If it were snug enough, then it would be just a matter of using a heated blade to cut the glue stick and roll crimp, or vice-versa. I might not trust it to seal as well, and so far, I have seen nothing detrimental in applying the hot glue directly over the shot, and I know there’s a good seal. And because of the relatively low pressure of these rounds, I’ve been using cases that have gone through multiple loadings. I can’t say if it’s really necessary since the shot weight and count vary, seemingly for each round, but all of the cases used so far have been trimmed to 1.280”.

We got out to the range yesterday, 12/12/19. The newest loads represented the changes I felt were necessary from the two previous loads. I’m very pleased to say that the extrapolated charge, 6.5 grains of True Blue has not been changed for any of these loads, and its uniformity was proven yet again. The primer reverted back to the standard CCI500, and everything I had hoped to see with this latest batch of loads were manifested. The biggest problem that I have faced during the entire testing process has been getting my Pro Chrono to provide the velocity ratings. At best I can say that the most accurate readings were above 1002 FPS and below 1048 FPS. But had I tested from a 6” barrel, velocity would have been higher while Speer stated in their #11 manual that a velocity loss of up to 150 FPS should be expected for 4” barrels. So I’m essentially getting velocity from a 4.2” GP100 that is in the same range of the loads from the Speer #11. And because True Blue is as uniform as it is, I wouldn’t expect such a sizable difference in velocity for a 6” revolver or a sub 3” revolver.

There were only 9 pellets that landed outside of the 7.5” scoring ring, and only one of them was beyond 1” of the outer scoring ring. I’m more than satisfied with the number of pellets that landed in the 9 and 10-rings. A total of 19 pellets of the larger and heavier hitting 7 ½ shot. That’s about 25% of the total of what I counted in my last loading while 95.1 grains was the total weight of the shot. I have absolutely no doubt that this is a load I will carry when snake conditions warrant. So, since a picture paints 1000 words, that’s how this article will end.

God Bless, be safe, and good shooting to you all,

Kevin